Understanding environmental stress testing with test chambers is an important part of ensuring that products are reliable and safe for their intended use. This type of testing requires a controlled environment, so test chambers are used to recreate the conditions the product will experience in its operating environment.

By simulating real-world scenarios, engineers can identify potential weaknesses or design flaws, allowing them to be addressed before they cause problems in the field. This article will explore how these tests are conducted, as well as why environmental stress testing is necessary for many types of products.

What is Environmental Stress Testing?

Environmental Stress Testing (EST) is an important technique used to evaluate the performance and reliability of products under a range of different environmental conditions. EST can be used to test for various factors such as temperature, humidity, shock/vibration, and other external forces.

By subjecting products to specifically designed tests within a test chamber, manufacturers can measure how their product will stand up in extreme environments or over extended periods.

With this knowledge, they are better equipped to make improvements before releasing their product onto the market. Test chambers provide a controlled environment where engineers can accurately simulate any type of environmental condition needed for testing purposes.

From hot and humid climates to cold temperatures or rapid changes due to altitude variations, these chambers allow users to recreate real-world scenarios with precision and accuracy to maximize their understanding of a product’s potential performance when exposed to harsh conditions.

Types of Test Chambers Used for Environmental Stress Testing

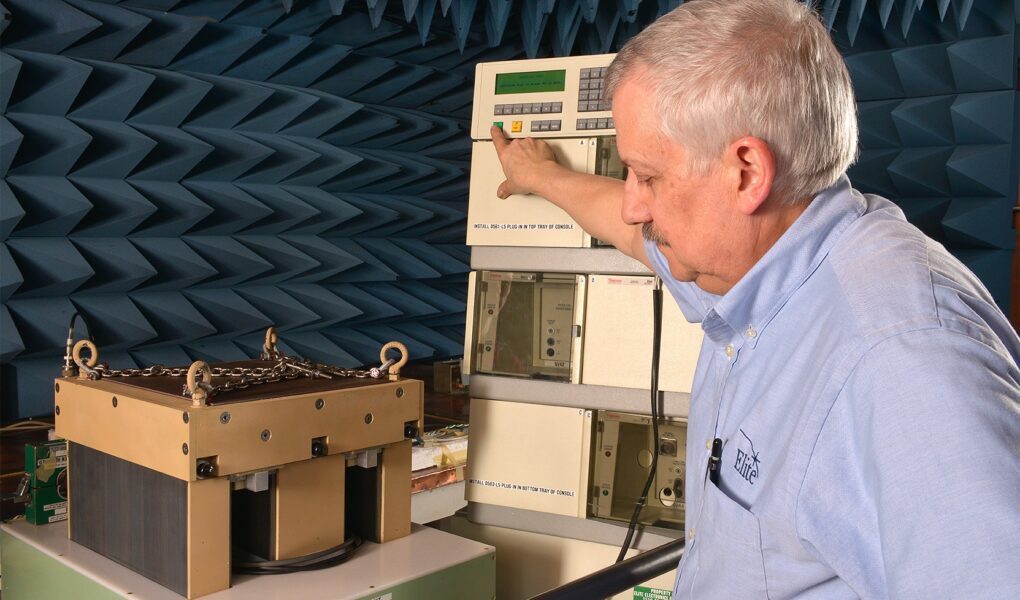

Environmental Stress Testing (EST) requires a special test chamber to simulate the conditions that a product or system may experience in real life. Test chambers are designed and built for specific applications, such as temperature testing, vibration tests, and humidity tests. Below is an overview of some of the most common types of test chambers used for EST:

- Temperature Chambers: Temperature Chambers are used to performing thermal shock testing by rapidly cycling between extreme temperatures. These chambers come with adjustable air flow and cooling systems that can provide precise control over their environment.

- Vibration Chambers: Vibration Chambers allow engineers to monitor how a product responds when subjected to vibration forces from multiple directions. The vibrations emitted from these chambers mimic the actual vibrations experienced during use, allowing engineers to identify potential failure modes before they occur in real-world scenarios.

- Humidity Chambers: Humidity Chambers replicate wet environments including rain, fog, steam baths, etc., which helps determine if products will be able to withstand repeated exposure without catastrophic failures due to corrosion or other moisture-related issues.

- Altitude Simulation Chamber: The altitude Simulation Chamber simulates high altitude conditions while controlling temperature fluctuations at different altitudes so as not to disrupt operations. This type of chamber is particularly useful for aerospace equipment manufacturers who need assurance that their devices will function properly in flight under various environmental conditions encountered during flight time

Common Applications for Environmental Stress Testing

Environmental Stress Testing is a common application in various industries and tests the endurance of components, products, and materials under extreme conditions. By exposing them to temperature extremes or humidity variations, manufacturers can determine how well their products will perform under harsh environmental conditions.

As such, Environmental Stress Testing with Test Chambers is widely used for testing military-grade systems as well as consumer goods such as smartphones, cars, computers, and other durable items.

In addition to determining the reliability of a product’s design principles against external factors like weather changes or overvoltages from power surges, these tests can also be used to assess the performance differences between different designs or products for comparison purposes.

Considerations for Selecting the Right Test Chamber for Your Needs

When selecting the right test chamber for environmental stress testing, it is important to consider both your current and future needs. Making sure that a test chamber has all the features needed for successful testing is key; this includes having adjustable temperature, humidity, pressure, and airflow capabilities as well as multiple ports for connecting sensors or probes.

Additionally, one must ask themselves if one needs an insulated chamber with thermal barriers to achieve precise temperature control or whether insulation isn’t necessary due to the environment being tested. Furthermore, understanding what type of materials are used in the construction of a test chamber will help determine how durable and reliable it will be over time.

Finally, when making a decision on which test chamber is best suited for your needs make sure you consider factors such as size (internal dimensions), weight capacity restrictions, noise levels, and energy efficiency ratings so that you can get the most out of your investment.